Positive Impact of Metal Fabricators and 3D Printing on Business

Introduction

Welcome to QuickParts.com, your leading source of information on metal fabricators and the power of 3D printing in the business world. In this article, we will explore the myriad benefits that these innovative technologies bring to various industries, with a particular focus on the incredible advantages offered by 3D printed investment casting patterns.

Advantages of Metal Fabricators

Metal fabricators play a crucial role in modern manufacturing processes. These skilled professionals possess the expertise and resources necessary to transform raw materials into high-quality metal products, meeting specific design requirements. QuickParts.com partners with some of the most reputable metal fabricators in the industry, ensuring unmatched quality and precision to our clients.

Unparalleled Precision

One of the key benefits provided by metal fabricators is their ability to achieve unparalleled precision in their work. With state-of-the-art equipment and extensive experience, they can fabricate metal parts with utmost accuracy, ensuring a perfect fit and meeting tight tolerances. This level of precision minimizes the risk of errors and rework, ultimately saving time and resources for businesses.

Enhanced Durability

Metal fabricators utilize high-quality materials that offer excellent strength and durability. By expertly shaping and forming these materials, they produce metal components that withstand rigorous conditions and provide long-lasting performance. Whether it's for heavy machinery, automotive applications, or structural projects, metal fabricators produce components that can withstand the test of time.

Customization and Flexibility

Another significant advantage of metal fabricators is their ability to provide customized solutions to businesses. As every industry has unique requirements, metal fabricators offer bespoke services, tailoring designs to meet specific needs. They can work with a wide variety of metals like stainless steel, aluminum, or titanium, adapting their processes to suit the desired specifications of their clients.

Efficient Time-to-Market

Metal fabricators understand the importance of efficient time-to-market in today's competitive business landscape. By leveraging advanced fabrication techniques and optimizing production workflows, they can significantly reduce lead times and accelerate project completion. This efficiency allows businesses to meet tight deadlines, gain a competitive edge, and seize new market opportunities.

Revolutionizing Manufacturing with 3D Printing

Now, let's delve into the transformative capabilities of 3D printing and its profound impact on the manufacturing sector. At QuickParts.com, we have witnessed firsthand how 3D printing is revolutionizing the way businesses develop and produce intricate parts and components.

Unmatched Design Freedom

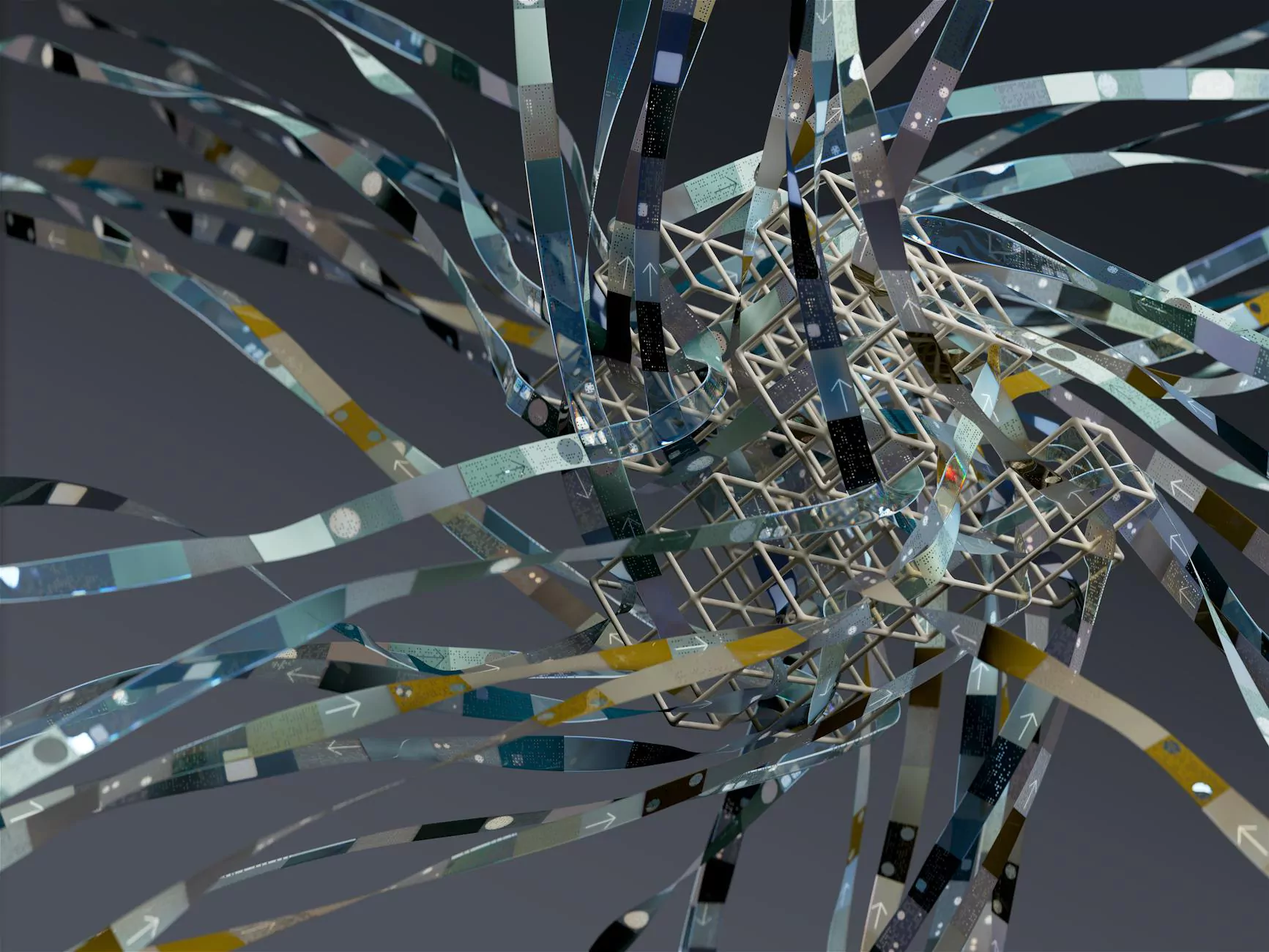

Unlike traditional manufacturing methods, 3D printing unlocks unrivaled design freedom. By translating digital models into physical objects, businesses can create highly complex and intricate geometries that were once considered impossible. The ability to print parts with internal cavities, organic shapes, and intricate lattice structures opens up new possibilities for innovation across industries.

Cost-Effective Prototyping

Prior to the advent of 3D printing, prototyping was a costly and time-consuming process. With traditional manufacturing, creating a single prototype required significant investment in tooling, molds, and manual labor. 3D printing eliminates these constraints by enabling rapid, cost-effective prototyping. Businesses can now iterate designs quickly, saving time and reducing costs associated with traditional prototyping methods.

Leaner Inventory Management

Inventory management is a critical aspect of any business. Traditionally, businesses needed to maintain large inventories to meet fluctuating demand. 3D printing introduces the concept of on-demand manufacturing, allowing businesses to produce parts as and when needed. By adopting 3D printing technologies, businesses can minimize inventory costs, reduce waste, and achieve a leaner, more efficient supply chain.

3D Printed Investment Casting Patterns

Now, let's focus on the game-changing impact of 3D printed investment casting patterns. Investment casting is a highly precise manufacturing technique used to create complex metal parts. Traditionally, creating investment casting patterns required time-consuming and costly tooling processes. However, 3D printing has revolutionized this process by enabling the direct production of investment casting patterns using advanced additive manufacturing techniques.

By utilizing 3D printing for investment casting patterns, businesses can significantly reduce lead times and costs associated with traditional pattern-making methods. The digitalization of the pattern production allows for greater design flexibility, rapid iteration, and customization. With a quick turnaround time, businesses can effectively accelerate the entire investment casting process, from pattern creation to final component production.

Conclusion

The combined power of metal fabricators and 3D printing is reshaping the manufacturing landscape, driving innovation, efficiency, and cost-effectiveness. By leveraging the precision and expertise of metal fabricators, businesses gain access to high-quality metal components that meet their specific requirements. Meanwhile, 3D printing empowers businesses with revolutionary design freedom, rapid prototyping, and optimized inventory management.

QuickParts.com aims to be your go-to resource for all things related to metal fabrication, 3D printing, and their positive impact on business. Stay tuned to our website for the latest updates, expert insights, and success stories from industries embracing these transformative technologies.