Unlocking the World of DIN Hydraulic Fittings: Your Comprehensive Guide

DIN hydraulic fittings play a crucial role in various industrial applications, ensuring efficient and reliable fluid transfer across systems. Established by the Deutsches Institut für Normung, these fittings adhere to internationally recognized standards, enhancing compatibility and safety in hydraulic systems. This guide aims to provide you with a complete understanding of the DIN hydraulic fittings chart, their applications, types, and why they are indispensable in the manufacturing and maintenance sectors.

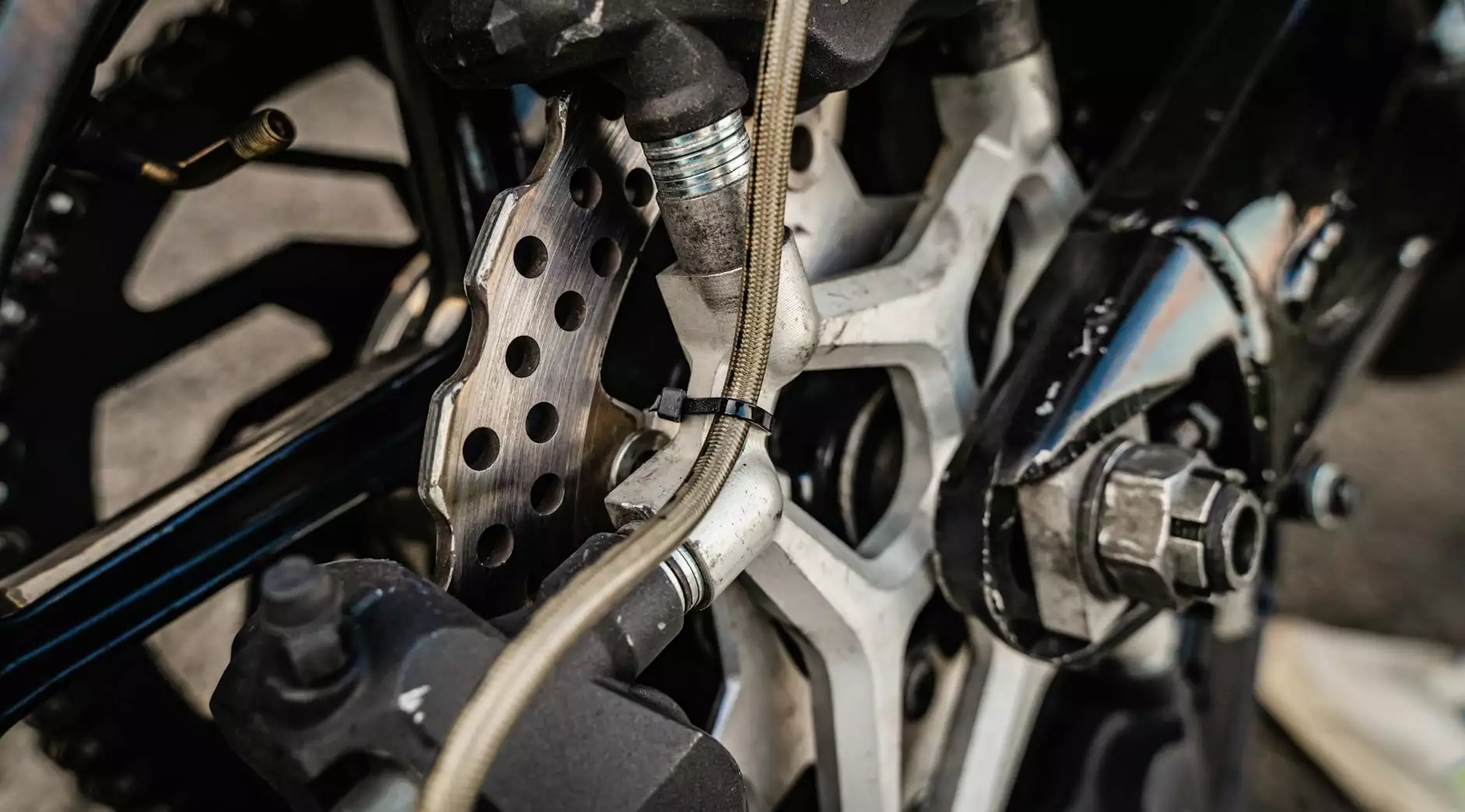

What are DIN Hydraulic Fittings?

DIN hydraulic fittings are standardized connectors that ensure the secure attachment of hoses and pipes in hydraulic systems. They are defined by unique specifications established by the DIN, which regulates dimensions, shapes, and technical requirements for seamless integration. This standardization promotes interoperability between different manufacturers and components, allowing for a smoother assembly process.

The Importance of the DIN Standard

The DIN standard was created to minimize variations in design, materials, and manufacturing processes for hydraulic fittings. Adhering to a standardized set of codes means that the fittings can be reliably used in various industries, including:

- Aerospace

- Agriculture

- Construction

- Manufacturing

- Automotive

By providing a consistent design, the DIN standard enhances safety and efficiency in fluid management systems, avoiding leaks and failures that could lead to costly downtimes.

Exploring the DIN Hydraulic Fittings Chart

To fully grasp the significance of DIN hydraulic fittings, it's essential to understand how to read the DIN hydraulic fittings chart. This chart outlines the various fittings available in the market, their specifications, and their respective applications. Below are some key elements included in the chart:

- Fitting Types: Different fittings for various hydraulic applications including, but not limited to, straight, elbow, tee, and swivel types.

- Dimension Specifications: IPC (Inner Pipe Diameter), O.D. (Outer Diameter), and thread specifications necessary for compatibility.

- Material Types: Common materials include steel, stainless steel, and brass, each suitable for specific pressure and temperature requirements.

- Pressure Ratings: Details the maximum pressure that the fittings can handle, critical for safe operation.

Types of DIN Hydraulic Fittings

The variety of DIN hydraulic fittings available caters to numerous hydraulic applications. Here's a closer look at some of the most common types:

1. DIN 2353 Fittings

DIN 2353 fittings are primarily used in the construction and maintenance of hydraulic systems. They are characterized by their reliability and high-performance levels. These fittings require less space and are easy to assemble.

2. DIN 2401 Fittings

This type of fitting is suitable for high-pressure applications, often found in industrial machinery and tools. The distinctive design allows for a robust connection that minimizes the risk of leakage.

3. DIN 40430 Fittings

DIN 40430 fittings are frequently used in agricultural machinery. Their design is tailored for durability and can withstand harsh environmental conditions, ensuring the performance remains consistent over time.

4. DIN 32676 Fittings

This range is specifically tailored for food and pharmaceutical industries, where hygiene and cleanliness are paramount. They offer smooth surfaces that are easy to clean and maintain.

Applications of DIN Hydraulic Fittings

DIN hydraulic fittings are utilized in various industrial applications that require efficient fluid transfer. Here are some of their notable applications:

Agricultural Equipment

In the agriculture sector, hydraulic systems are fundamental in tractors, harvesters, and other machinery. The use of reliable DIN hydraulic fittings ensures that farmers can depend on their equipment to perform efficiently.

Construction Machinery

Heavy equipment such as excavators, loaders, and bulldozers rely on hydraulic systems to operate efficiently. The correct DIN hydraulic fittings can significantly reduce the risk of hydraulic failure, leading to increased productivity on the job site.

Automotive Industry

Hydraulic systems in vehicles play a vital role in steering and braking. The durability and reliability offered by DIN hydraulic fittings are crucial to maintaining vehicle safety.

Aerospace Applications

The aviation industry demands the highest standards for hydraulic systems. DIN hydraulic fittings are utilized to ensure the safe operation of vital systems in aircraft.

Why Choose DIN Hydraulic Fittings?

Choosing DIN hydraulic fittings offers numerous advantages for your projects:

- Standardization: Compatibility across various manufacturers reduces downtime and ensures easy replacement of components.

- High Performance: Designed to handle high pressures and harsh conditions, these fittings enhance system reliability.

- Safety: Adhering to DIN standards ensures that safety regulations are met, minimizing risks associated with fluid transfer.

- Versatility: A wide range of fittings caters to various industries, making them suitable for multiple applications.

The Future of Hydraulic Fittings

As technology progresses, the hydraulic fittings industry is seeing innovations aimed at enhancing performance and safety. Advanced materials with improved corrosion resistance and lower weights are becoming standard, while designs are continually optimized for ease of manufacture and assembly.

Conclusion

Understanding the intricacies of DIN hydraulic fittings is essential for anyone involved in industries that depend on efficient hydraulic systems. The DIN hydraulic fittings chart provides a roadmap for selecting the appropriate fittings for your needs. By adhering to DIN standards, businesses can ensure compatibility, performance, and safety, leading to enhanced operational efficiency and reduced costs.

For more information on purchasing high-quality DIN hydraulic fittings, visit fitsch.cn. Our extensive range of fittings is designed to meet the varying needs of industries worldwide. Trust us to provide reliable solutions that stand the test of time!